May 28, 2019

The advantages of outsourcing a company's logistics functions — operational and service requirements from warehousing, fulfilment and inventory management, to components distribution & assembly — are conclusive.

We wanted to provide a quick presentation giving an overview of how you can get improvements from using a specialist logistics partner. This course of action is almost certain to provide better margins, flexibility, visibility & tracking.

OEM logistics: from 3PL to VMI and beyond

Find the embedded powerpoint below, or go to our Slideshare.

Powerpoint on the advantages of 3PL, VMI and 5PL services

Third-party logistics services transcript

Here's the transcript for Acorn's VMI/3PL/5PL presentation.

- VMI / 3PL / 5PL SUPPLY CHAIN SERVICES

- The advantages of outsourcing a company's logistics functions — operational and service requirements from warehousing, fulfilment and inventory management, to components distribution & assembly — is conclusive. A supply chain specialist

- E2open research brief: Outsourcing manufacturing: a 20/20 view Improvements from a specialist logistics partner Better margins, flexibility. Need for visibility & tracking.

- Service overview Key services Vendor Managed Inventory (VMI) 3PL / 5PL Kitting & Sub-assembly Components supply MRO/PPE vending Supply chain services Warehouse consultancy Inventory management Sales & Operational Planning Kanban systems Supply chain technologies Planning services Inventory analysis & planning Systems requirements/resourcing Outsourcing & tender management MRP & ERP Process design & strategy

- Integrated services Vendor Managed Inventory Streamlined inventory management and order fulfillment, better replenishment and demand planning with VMI and Kanban bin systems. 5PL Aggregates and builds on 3PL to oversee all supply partners, and obtaining efficiencies by developing and overseeing a client’s full supply chain as a true collaborative partner. 3PL A Third Party Logistics solution bundles procurement, transportation and distribution functions into an integrated solution for planning, coordinating, and delivering inventory. Customise your depth of integration and level of outsourcing

- VMI Macro benefits — Better planning. — Increased customer service. — Just-in-time (JIT) inventory. — Advanced forecasting. — Reduction in sales costs. — Realtime inventory snapshots. Efficient ordering, reduced inventory and logistics processing costs Advantages — Improved overall service level. — Eliminate stock-outs. — Improved product ordering process. — Eliminate line-downs. — Decreased administration time. — Better stock visibility. — Higher inventory control. Controlling inventory is a challenging task, requiring technical expertise and precise stock management. Acorn undergoes a bespoke process, analysis and install for each client.

- 3PL Specialist planning, coordination and delivery of your component supply Main benefits — Take advantage of professional supply chain experience. — Leverage our extensive procurement network and resources. — Develop a stronger logistics capacity by employing a specialist partner. — Customised service created as a bespoke fit for your supply chain. — Maximise your order flexibility and inventory control. — Optimised, fully staffed, modern warehousing. — Fully certified to the highest ISO quality standards. Acorn’s solutions create a lean inventory and a more robust and resilient supply chain through demand planning, vendor management and procurement. 3PL adds additional supply chain value to your business.

- 5PL Partnering to collaborate on, and optimise your full supply chain network Key advantages — Full utilisation of resourcing advantages. — State-of-the-art supply chain implementation. — Increased agility in manufacturing process. — Seamless inventory and production operations. — Greater cost savings through consolidation and coordination of supplier network. — Better carbon and energy savings. — Integrated management of resources, capabilities & technologies delivers competitive advantage. Acorn work hand-in-hand with you to develop and implement a full supply chain solution for your manufacturing needs. We act as a central point to manage and maximise value in all your supplier needs.

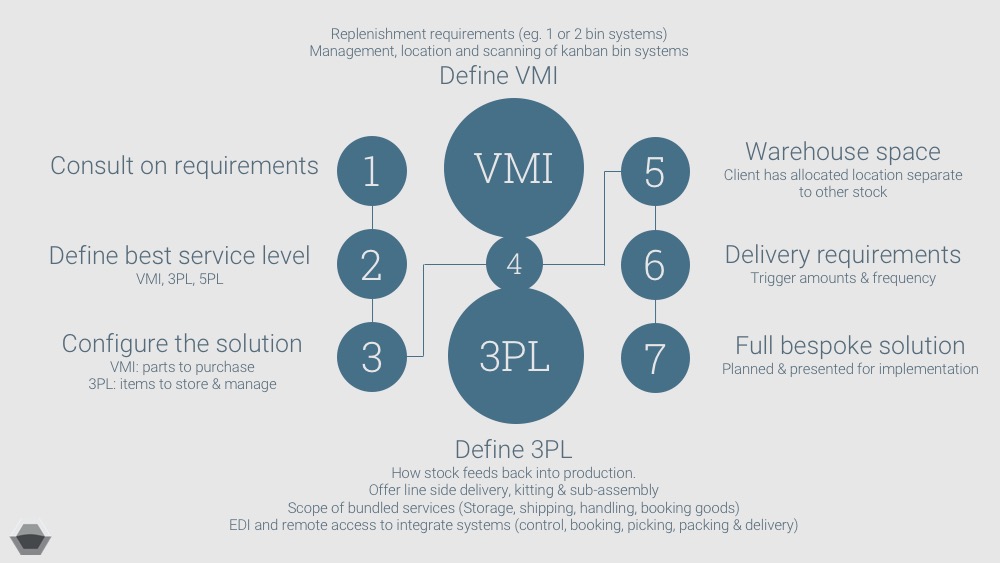

- Acorn create bespoke supply chain solutions uniquely tailored to each client’s requirements. We offer open and transparent servicing with high standards in sustainable and ethical business practice. Our process

- Consult on requirements 1 Define best service level VMI, 3PL, 5PL 3PLConfigure the solution VMI: parts to purchase 3PL: items to store & manage Define 3PL How stock feeds back into production. Offer line side delivery, kitting & sub-assembly Scope of bundled services (Storage, shipping, handling, booking goods) EDI and remote access to integrate systems (control, booking, picking, packing & delivery) Warehouse space Client has allocated location separate to other stock VMI Replenishment requirements (eg. 1 or 2 bin systems) Management, location and scanning of kanban bin systems Define VMI Full bespoke solution Planned & presented for implementation Delivery requirements Trigger amounts & frequency2 3 5 6 7 4

- Acorn is a family-run firm with over 40 years experience in supply chain solutions Our Service Values

- Procurement Specialising in OEM direct line feed delivery, with high quality, best value components Enhanced C-parts procurement and management using a specialist supplier with comprehensive catalogue and warehouse range availability 150+ product ranges Access Hardware Wire & Cable Crimps & Terminals Pneumatic & hydraulic fittings and adaptors Tubing Adhesives/Sealants/Tapes/Lubricants Electrical supplies Thread Protection

- Industrial components Sourcing from 30,000+ parts PPE & MRO tools All leading brands & manufacturers Fasteners 50+ BS & 100+ DIN standards Precision machining Tolerances up to +/- 0.003 gram