Cutting tools are found in almost every warehouse and manufacturing setting. Our new line dramatically reduces the risk of workplace injury from box cutters and utility knives, with cutting-edge technology safety blades (excuse the pun).

Dangerous blades cause lacerations. Our slice line of safety blades, knifes and cutters offer the next generation in cutting technology.

Special ceramic blades that are safe to the touch, durable, & don't rust

Sharpened differently, slice's proprietary grind is safer to the touch. 100% Zirconium oxide and 1.3mm thick, they are less breakable.

They balance user safety with tool effectiveness, offering manual, auto and smart retracting options.

Best-in-class ergonomics results in less muscle effort and wrist movement, reducing strain.

Increase your workplace safety and go to zero injuries with superior safety & longevity by utilising this next-generation blade technology.

What cuts you? Handle or blade?

Better safety blades reduce workplace injury

The slice product line includes: Box cutter (auto-retractable option), pen cutter, folding utility knife, mini cutter, carton cutter, industrial knife, scraper, craft knife, precision knife, precision blades, ceramic scalpels, safety cutter rings, EDC folding knife, scissors (including self-opening, and rotary variations).

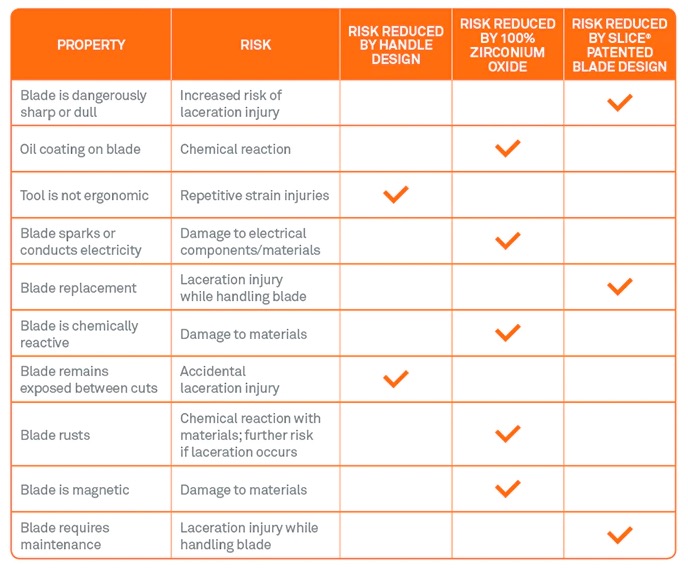

Remove the main risks of traditional knives and get the slice advantage:

Blade too sharp or too dull = laceration.

Blade has oil coating = chemical reaction.

Non-ergonomic handle = repetitive stain injury.

Conductive blade = damage to electrical components.

Frequent blade replacement = laceration.

Chemically reactive blade = damage to materials.

Blade exposure between cuts = laceration.

Rusty blade = chemical reaction, tetanus.

Magnetic blade = damage to materials.

Blade maintenance required = laceration.

Explore the slice range

Get our linecard to check out the full slice range and add it to your next order from Acorn.