Take control of your inventory management and order fulfillment with Vendor Managed Inventory (VMI). Profit from more efficient ordering, reduced inventory and logistics processing costs, better replenishment and demand planning.

Controlling your inventory is a challenging task, requiring technical expertise and precise stock management. Partner with an experienced VMI provider.

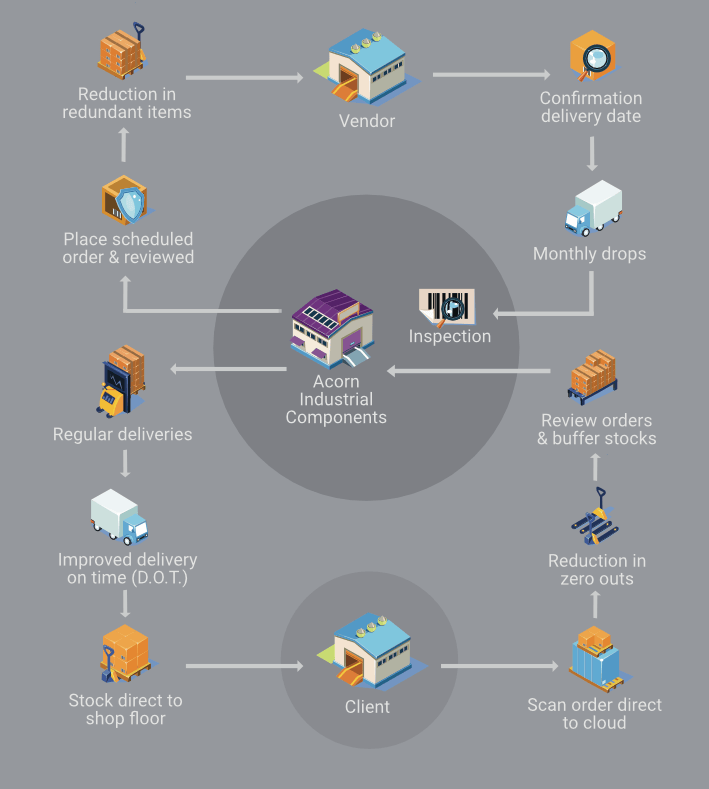

Acorn undergoes a bespoke process, analysis and install for each of our clients. We provide a full consultation along with install of appropriate technology and processes. You can see a visual representation of our process in the infographic.

Outsourcing either in full, or a segment, of your supply chain logistics operation to an expert provider allows you to unleash the full insights and benefits of the vendor managed inventory system.

Partnering with an experienced VMI provider allows you to concentrate on your core strengths while benefitting from more efficient supply and inventory.

Acorn has decades of experience in logistics planning and inventory management. OEM clients appreciate the elimination of excessive administrative time and costs with a full supply solution.

The benefits of vendor managed inventory

— Improved overall service level

— Reduction in stock-outs

— Improved product ordering process

— Eliminate line-downs

— Decreased administration time

— Better stock visibility

— Higher inventory control

— Better planning

— Increased customer service

— Just-in-time (JIT) inventory

— Advanced forecasting

— Reduction in sales costs

— Realtime inventory snapshots

Steps for successful VMI

Define service level expectations

The objective is effective supply and delivery of inventory with clear and constant communication between the supplier and customer being essential. If this is not addressed, the service is likely to be terminated quickly with neither side gaining any benefits. It is important to set clear expectations which are realistic and satisfactory for the level of service the client wishes to receive with VMI. Service level objectives need to be explicit with monitoring, adjustment and intervention when necessary.

Create information access and sharing protocols

Order fulfillment and restock in a timely manner can only be achieved through synchronising and sharing data on stock levels and usage. An efficient, effective two-way system of data monitoring through EDI/automated inventory information flows shared between client and supplier unlocks inventory and delivery efficiencies central to the VMI approach. Demand planning through the communication of delivery forecasting and production scheduling is essential for upstream planning and order timings to work.

Implement regular feedback loops

Communication is key in optimising vendor managed inventory services. The VMI programme, to be outsourced and implemented successfully, needs to make sure stakeholder OKRs (objectives and key results) are being met, and reconciled with component and supply conditions. From the supply partner side, effective communication of logistics network issues (whether geo-political, resource or distribution based, for example) can impact and positively contribute to client production planning. When expectations are not met, or either the production or logistics situation changes rapidly, it is essential for the client and supply partner to have a regular channel to clarify and resolve issues. Problem solving becomes easier and quicker.

Vendor managed inventory: get even more benefits

Full 3PL/4PL solutions can unlock even greater competitive supply chain advantages, but requires further integration between the operations of manufacturing client and supply chain logistics partner. As a rule trust will have been needed to be built up between the companies, and an operating track record demonstrated with a proven and excellent working relationship. Third Party Logistics involves a deep and integrated relationship between manufacturing and logistics functions on both sides that is a step up from VMI.

Vendor Managed Inventory is a fantastic and well-trodden pathway to a third party logistics solution (3PL and its other flavours. 4PL, 5PL, et al) , while in its own right being an easier to implement foundational value-added logistics service.

Ready to find out more?

Drop us a line today to explore our services

Sources:

CIPS: Vendor Managed Inventory